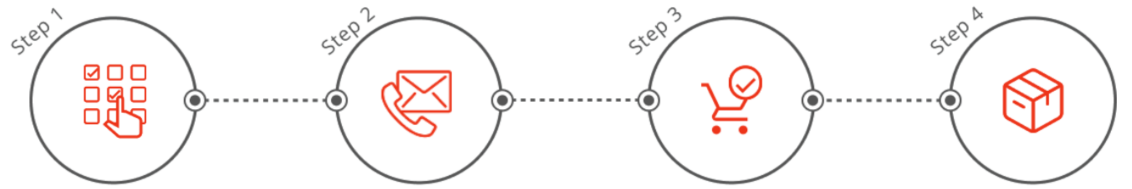

How It Works

OUR PROCESS

We sell to distributors, resellers, and designers who will need to provide a state Sales Tax Exemption or State Resell Certificate.

We can help you find a reseller if you’re an end user.

Select Your Table Bases

Work with our team to find which table bases best fit your distributor, reseller, or designer needs. With multiple table base designs, we guide you through product options to tailor a quote.

Request A Quote

Complete the quick form and include all applicable company and/or project information to get started.

Place A Purchase Order

After finalizing and approving your quote, place a PO with our team. After the order has shipped, we will send over an invoice.

Receive Your JI Bases

We can ship within the next business day from our domestic warehouse to you or directly to your customer under your name.

Ready To Place An Order? CONTACT US

Frequently Asked Questions

Why cast iron?

Cast Iron is a common strong metal that can be infinitely recycled. While steel bends and flexes easily, cast iron does not give under pressure. Our cast iron top plates are built to spread and hold the weight of the tabletop. This keeps your customer’s table bases sturdy and level.

What's the lifetime guarantee?

We stand behind our cast iron table bases and will gladly replace any cast iron table base if needed for breakage, no questions asked.

What size table base will my customers need?

Use our handy sizing chart to narrow down your options based on tabletop size. On average, our table bases can hold most tops within an approximate weight limit of 10 pounds per square foot. If you need a heavier base, please include the table top measurements (length, width, etc.), materials (laminate, wood, stone, etc.), and weight estimates in your quote request.

What can my customers find in the packaging?

Our 3-piece construction table bases will include a cast iron top plate, a column, and a base plate with pre-installed glides. Depending on the model, your customers may also receive an assembly platform, fiber centering ring, and/or a welded footring.

How can my customers assemble their new table bases?

Assembly is quick and easy! Your customers can find our assembly instructions on the exterior of your packaging. We include an assembly platform for ease—and after use, it can be recycled! Review our How-To videos showing the assembly processes of our cast iron and stainless steel bases.

Assembling Your Base

-

Cast Iron

Our cast iron table bases can be assembled in under 1 minute! Ease of assembly is just one amazing feature of a JI Base. Start with the base upside down so you can secure both plates to the column. Assembly instructions are printed right on the box!

Insert the bolt through the TOP plate.

Insert the bolt through the TOP plate. Set the top plate onto the assembly platform.

Set the top plate onto the assembly platform. Secure the column over the bolt in the top plate grooves.

Secure the column over the bolt in the top plate grooves. Mount the base plate on top around the bolt.

Mount the base plate on top around the bolt. Secure the locknut onto the bolt and tighten it firmly.

Secure the locknut onto the bolt and tighten it firmly. -

Stainless Steel

Unlike the cast iron bases, our stainless steel bases are assembled upright. Lining up the column notches with the steel plate on the base and top plates is required for proper assembly. The notches line up with the steel plate so that the column doesn’t shift.

Insert the bolt through the BASE plate.

Insert the bolt through the BASE plate. Set the base plate on the assembly platform.

Set the base plate on the assembly platform. Place the column over the bolt and align it with the base plate notches.

Place the column over the bolt and align it with the base plate notches. Mount the top plate on top and align it with column notches.

Mount the top plate on top and align it with column notches. Secure the locknut onto the bolt and tighten it firmly.

Secure the locknut onto the bolt and tighten it firmly.